A reader asked a few good questions, see below.

Q. Via this balancing method, did you reduce the amount of weight required?

A. In general, static balancing methods reduce the weight needed to balance a tire/wheel combination, and this is true for both bubble balancing and machine static balancing. Static balancing only balances a tire and wheel in one plane, vertically. More weight is needed for a dynamic balance, partially because dynamic balancing also helps correct lateral imbalance.

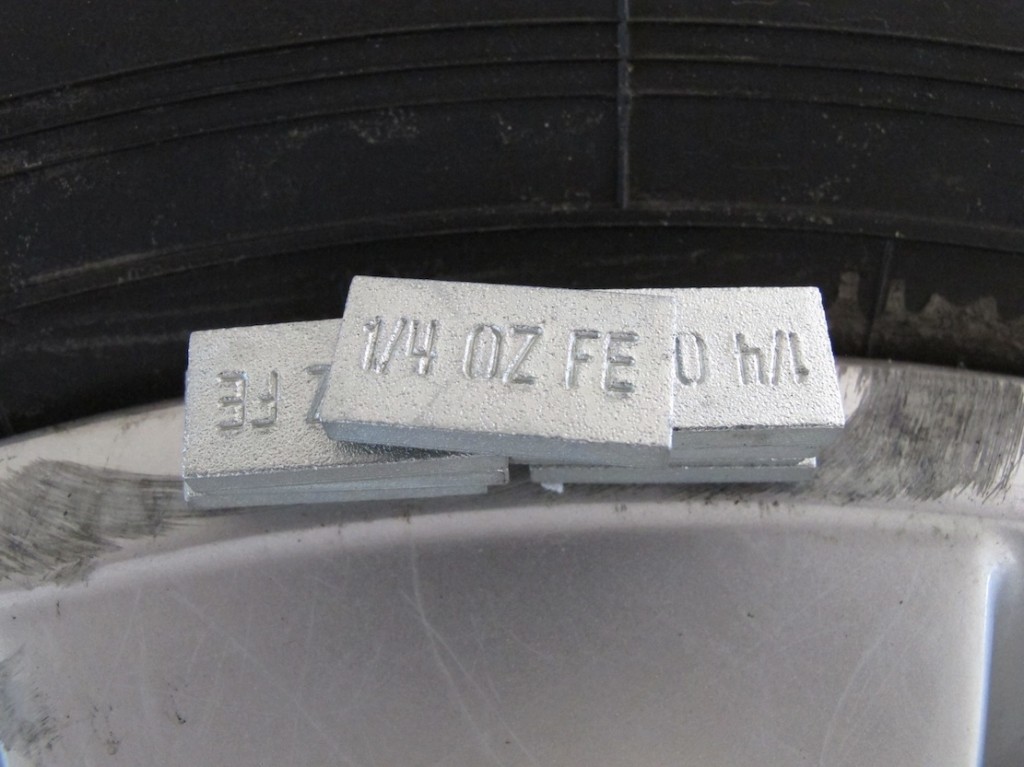

The amount of weight needed to balance a tire using this bubble balancer appeared similar to a machine static balance. Maybe slightly more weight and less precise.

Q. Have you tried rotating the tire on the rim to minimize added weight?

A. While using this bubble balancer there was no need to rotate the tires on the wheels, the weight needed to balance was not excessive once I was competent. Obviously it’s not easy for a man working with hand tools to breakdown a tire and rotate it on a wheel. However, many times in the past while having tires machine mounted & balanced I’ve had the tires rotated on the wheel. This was done is response to a tire/wheel combination that required more weight than I thought should be used.

How much is too much? That depends on the wheel (size, aluminum vs. steel) and the size, weight, and tread of the tire. I’m generally very particular and don’t want to feel any tire imbalance from a warmed-up tire. For my trucks, all of which currently run 33-inch tires, I’m typically happy if less than six ounces are needed for a static balance. Generally a few more are needed for a dynamic spin balance. When a new tire starts needing more than 8-9 ounces (dynamic) I like to rotate the tire on the wheel 180-degrees, hoping less weight will be required. This doesn’t always work, and sometimes the tire must be returned to its original position. The weight mentioned above are personal maximums, less weight is better. Regardless of the weight needed, more important is the quality and repeatability of the balance.

Q. Have you tried balancing the rim by itself?

A. I’ve checked the balance of wheels without tires, though I’ve never actually needed balance a wheel without a tire mounted. Checking the balance of a wheel has invariably showed that either the tire or the balance machine was the source of a problem, but of course wheels can be damaged. I’ve been using light, factory aluminum wheels and moderate sized tires for many years, and been lucky my heavily used wheels remain true.

Copyright © 2011 James Langan