Tuffy Security Products’ teenaged founder Shawn Gregory parked his Jeep at a mountain bike trailhead in 1989, and when he returned he found his Jeep burglarized and all his gear stolen. Gregory replaced the plastic center console with a stout, locking wooden box, which he was soon duplicating for friends. Steel replaced wood as the construction material, and another American entrepreneurial success story began. In 2008, Tuffy’s Jeep-centric product line was expanded to include options for the broader recreational market, as well as law enforcement vehicles.

If my trucks were not both Tradesmans, there is a center console safe I would have chosen to install, but it doesn’t fit my models. However, Tuffy does make other application-specific, and universal boxes and safes that do work with my Fourth Generation, 2500 Rams.

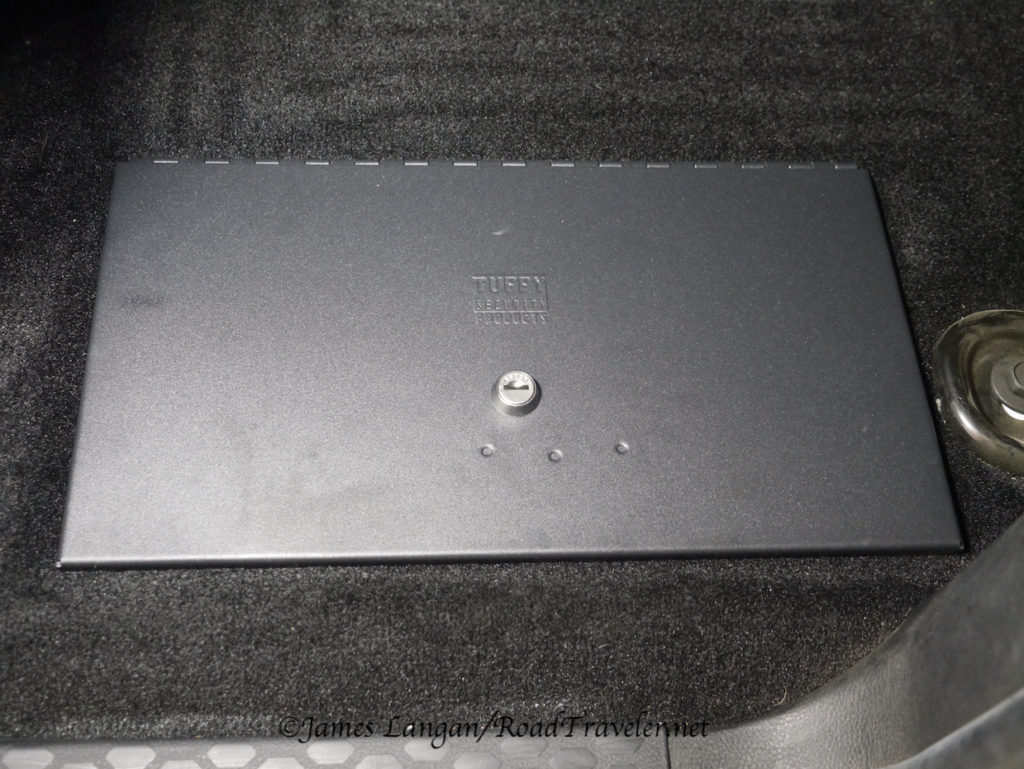

One is the heavy-duty, locking, under-floor Storage Security Lids constructed with 16 gauge and 1/8” thick welded steel ($89 each). These replace the factory plastic covers atop the backseat floor. The lids include Tuffy’s Pry-Guard locking system, a continuous steel hinge, and a 10-tumbler, double-bitted security key lock with built-in weather seals. (These do not fit the Mega Cab trucks.) The no-drill installation uses the factory holes and captive nuts, and are simple and easy to mount. However, I still have a few observations and tips on how-to do the job a bit better, with my typical attention-to-details.

Ram In-Floor Storage Security Lids Installation

Removing my rubber floor mat, opening the factory lids, lifting out the OEM plastic liners, then pulling the four T-30 Torx screws was all that was required to prepare to mount the Security Lids. After the OE parts were removed I noticed that there were five holes through the body, not just the four from the removed screws.

That fifth hole is for a stud on the bottom of the plastic factory lid, which has a rubber gasket at the top, obviously intended to create a seal and keep debris out, as shown in the photograph below. (This indexing hole for the factory plastic cover is at the outer/rear on the driver’s side, and at the front outer edge on the passenger side.)

Although unlikely in the short term, grit, moisture, and debris could reach this 1/4” hole on the bottom of the body over time or in certain circumstances. If one was to drive through, or get stuck in deep water or mud, intrusion could immediate. Anybody that drives in adverse conditions, including heavy rain, snow, slush, or dust knows that grime gets flung everywhere under the chassis, and leaving holes open to the inside is a bad idea. My solution? Spare plastic clips/plugs, like those used for securing trim pieces and such, slathered with outdoor silicone and stuffed into the holes.

The OEM plastic liners that nest inside the below-floor storage cavity can be reused, though one won’t be able to simply pull them out for cleaning like the OE setup, because they need to go under the mounting base of the Tuffy lids. As noted in the instructions, leaving the liners out is an option, which also maximizes storage space. Choosing to eliminate the liners increased the volume so that the set of spare Mopar fuel filters from Geno’s Garage I always carry in one of these bins, which always needed to be encouraged to fit inline across the bottom, now fit easily.

The factory lid screws had some type of sealant on the threads, so I added Permatex white goo Thread Sealant with PTFE to the 6 mm flat head screws provided (turned with a 4 mm hex bit). The Security Lids look great and fit impressively flush with the baseline floor height, allowing my big, one-piece Husky Floor Liner to lay as it did before. These in-floor lids are slick and beefy, and I was immediately happy I installed them.

There is a similar product that interested me, the Ram Underseat Locking Lid ($119), but I chose not to install it is because it’s only available for the driver’s side, not both sides under the rear bench seat.

Tactical Lock-Box

In addition to the locking lids, Tuffy also provided a Tactical Lockbox, and large and small Portable Safes for my use and evaluation; I’ll detail the Lockbox first. There are several variations in Tuffy’s Tactical Lockbox lineup, the one I ordered is 35” wide, by 12” long, by 5” high, (# 327–350120050–067–100–01), and retails for $469.

Their line of lockboxes were originally designed for the US government, for both high-security and portability of firearms and other valuable equipment. A patented, anti-twist, push button lock mechanism features a 10-tumbler, double-bitted security key with built-in weather seals. A user-changeable, combination push-button lock enables keyless entry. The box is designed to be secured with a padlock, and/or cable.

Because I rarely carry passengers, the backseat and floor of my crew cab are used for general cargo, mostly lighter items that don’t need to be secured (UFOs—unsecured flying objects—are dangerous during collisions). The black box sitting on a black floor mat, covered by the black windbreaker I always have at hand, concealed by tinted windows, makes it essentially invisible unless someone has already made entry with evil intent, at which time they’d need to contend with the locks.

My intended use for this Tactical Lockbox is as one might expect, for larger weapons and tools while out in the field, when they’re not actively being carried. Of course the box can also prevent theft of expensive photography equipment and other valuables as needed when adventuring away from my vehicular base.

Portable Safes

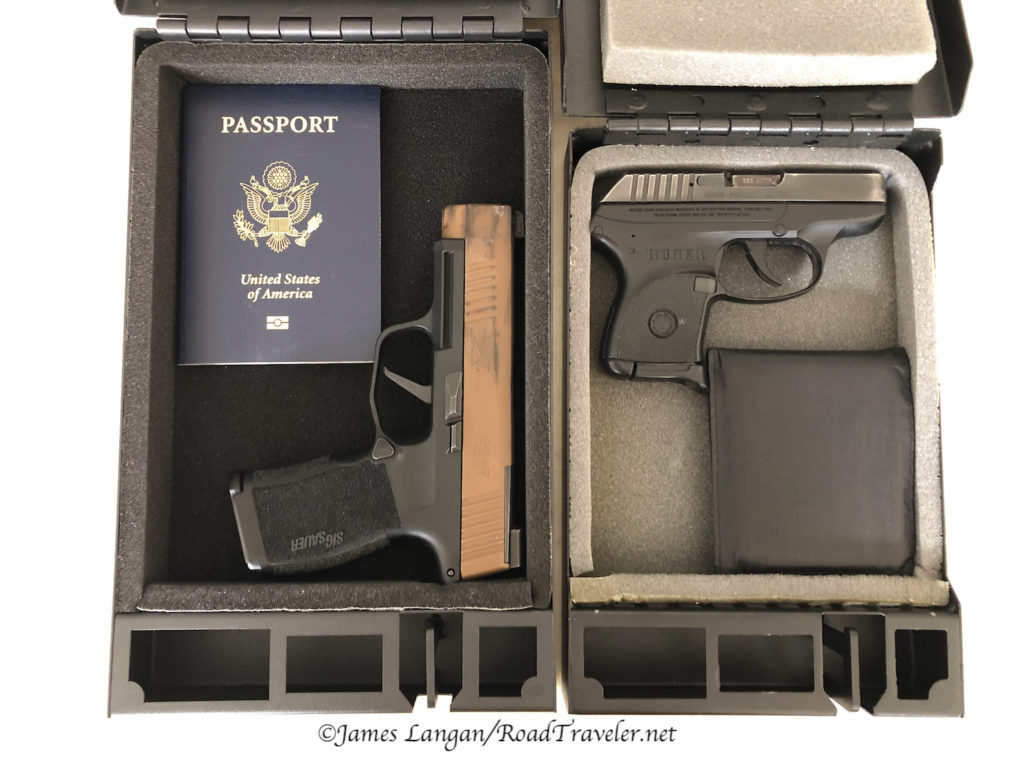

The final items are smaller and handy, two Universal Portable Safes, one that is marketed for full-size pistols ($99), and another for compact pistols ($79). Occasionally I will use these for firearms, however other small and slim valuables like wallets, passports and such can also be stowed inside.

Keyless entry is provided by a three-digit, user-set combination lock. A 2-foot long, 2000-pound-tested (and coated) steel cable secures the safe to any sturdy mounting surface (bolted seat leg in my case). The inside is lined with low-density foam to protect the contents, while compression bumpers keep the lid vibration free when closed.

The larger safe has been riding under my driver’s seat, completely out of sight, and rarely rattles, moves, or is irritating. These handy little boxes could be used other places too… like inside an RV, garage, or even inside a house, all one needs to do is tether the cable to something difficult to move.

For years I’ve known about Tuffy Security Products, but failed to look closely at what they might have to fit my vehicles. Even though I’m late to the party, I’m glad I made the trip.

Tell ‘em you read it on RoadTraveler.net!

James Langan

Instagram/TruthSocial @RoadTraveler

Resources:

Tuffy Security Products: tuffyproducts.com, 800-348-8339