Toyo Open Country R/T Tires

Toyo Tires’ rugged terrain R/T got the nod to be the first traction tread on my 2017 Ram regular cab. The versatility of a 60/40 design is ideal for my many miles both on- and off-highway. The R/T has had my attention since its introduction, but there was extra allure once it was offered in my favorite, niche, 18-inch size, the 285/75R18. Hearsay reports indicated that it was extremely quiet on-road, but I needed to experience this for myself.

Features And Benefits include:

-High Turn-Up, 3-Ply Polyester Sidewall Construction: Contributes to excellent durability, impact resistance, and handling.

-Optimized Pattern Arrangement: Reduces noise for improved driving comfort.

-Aggressive Sidewall Designs With Durable Sidewall Compound: Enhances traction and side impact protection and offers two slightly different sidewall tread designs for owner preference.

-Open, Scalloped Shoulder Blocks: Improves off-road traction; enhances grip in muddy, sandy, or snowy off-road conditions; and ejects mud and snow through the open channels.

-Stone And Mud Ejectors: Forces stones and mud from the grooves.

Mount, Balance, and Baseline

Five tires were ordered to ensure I had a spare that was not only the proper size but also offered adequate traction, which can be important when the spare is needed in difficult terrain. The new rubber balanced without drama on OEM aluminum wheels, typical for Toyo’s multi-segment designs.

One would think that the R/T’s outer lugs would lead to more noise compared to the familiar A/T II Xtreme. My initial run on the R/Ts had me thinking they were maybe slightly louder. However, when I put the A/T II Xtremes back on, and drove over the same section of freeway, I could not tell a difference. My back-to-back evaluations corroborated other reports that say the R/T is extremely quiet and sometimes indistinguishable from the A/T II Xtreme. Quite an engineering accomplishment! At most there may be a slightly different pitch to the noise they make and how they sound at lower speeds. To be perfectly clear, the R/T is not a silent tread design—get a highway tire if you want that—but they are impressively quiet for their appearance, void, and target audience.

Because I am a stickler for drivability, I was happy to discover that the Toyo R/T construction and design mated perfectly to my 2017 Pack Mule, which still sports the factory caster and camber settings; only the toe has been adjusted. There were no unusual handling or tracking quirks that required me to seek alignment or suspension adjustments. On level and smooth roadways no steering input correction was necessary. The truck continued straight and remained neutral, even when I played the old game: look mom, no-hands.

Some treads and chassis, even identical sizes from the same manufacturer, mesh differently. It is worth noting that the same size Toyo A/T II Xtreme drift to the right a bit on the ’17 Mule, yet they track perfectly straight on the 2014 Carryall crew cab that sports an SPC offset ball joint.

General Use And Wear Data

Over several months these Rugged Terrain treads saw at least a little of most surfaces. That means much pavement, but also plenty of dirt, gravel, snow, slush, and a little ice. The R/T is not a dedicated winter tire. It does okay, though maybe not quite as good as the familiar Toyo A/T II, which offers much more siping. The R/Ts have spent as little time as possible crossing mud…I don’t care for it, and heavy trucks and campers often flounder in mud.

Modern turbo-diesel pickups (not just Rams) often wear tread quickly compared to their gas-powered cousins. This has much to do with the massive amount of twist that the engines apply to the ground, and in this case the ‘Mule’s constant GVWR load. Manual transmissions are compounding factors, and both my Fourth Generation Ram/Cummins 2500s have the G56 6-speed (which I love). My driving style is generally smooth and efficient; however, there are times when I intentionally smash the accelerator, run the Cummins up-to the redline, and/or drive at higher speeds for hours. Therefore my tire wear data may represent a slightly fast wear scenario.

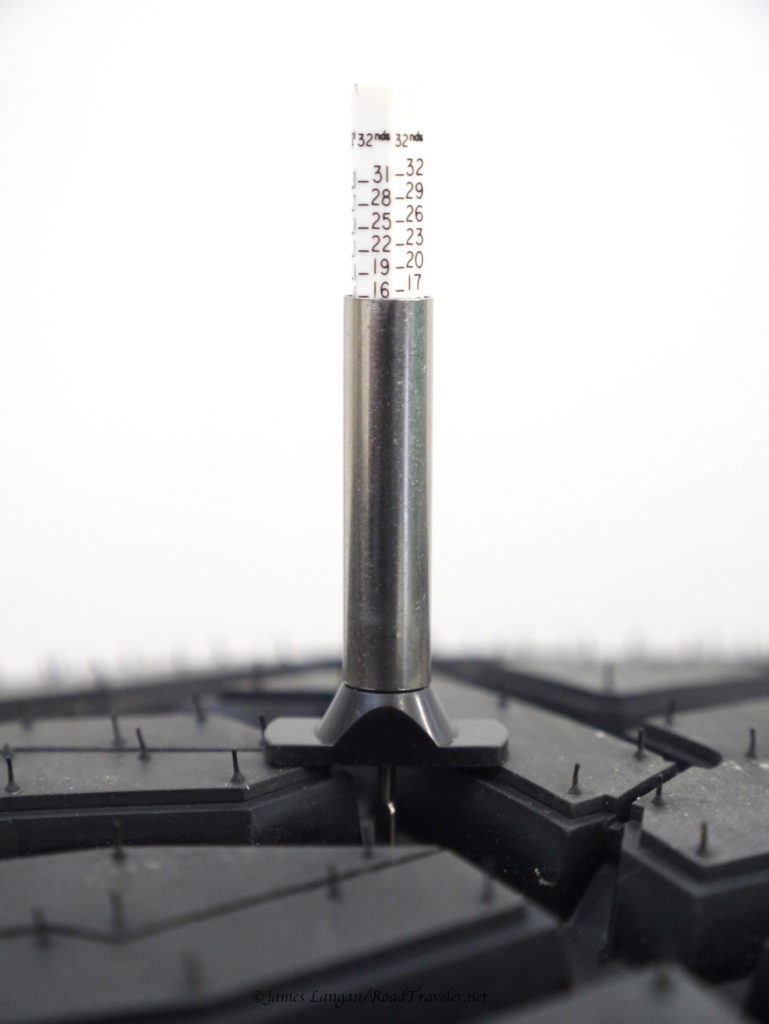

All LT-metric R/T sizes come with 16.4/32” of tread depth. This is 0.6” less than the same size Toyo A/T II, and the starting depth affects how many miles one might get out of tires before needing replacements. I prefer more rubber for both traction and longevity, but the 16.4/32” seems to be just enough. All floatation sizes start with 18.9/32-inches. Over 8,650 miles, rotating four, using a rearward cross pattern, these 285/75R18 Toyo R/T have delivered 1,965 miles per 1/32” of tread. This is similar to other tires that have yielded up to 2,100 miles per thirty-second. Wear often slows down as tread becomes shallower (if tires are rotated), and the measurements become more accurate as well.

Recently I mounted a different set of meats for a new evaluation, but the R/Ts remain in my shop mounted, balanced, and ready for continued use. Tire prices vary throughout North America, but in my part of the West the LT285/75R18E Toyo R/T are $340 each at my local Discount Tire.

Tell ‘em you saw it on RoadTraveler.net.

James Langan

Copyright James Langan/RoadTraveler. All Rights Reserved

Resource: Toyo Tires