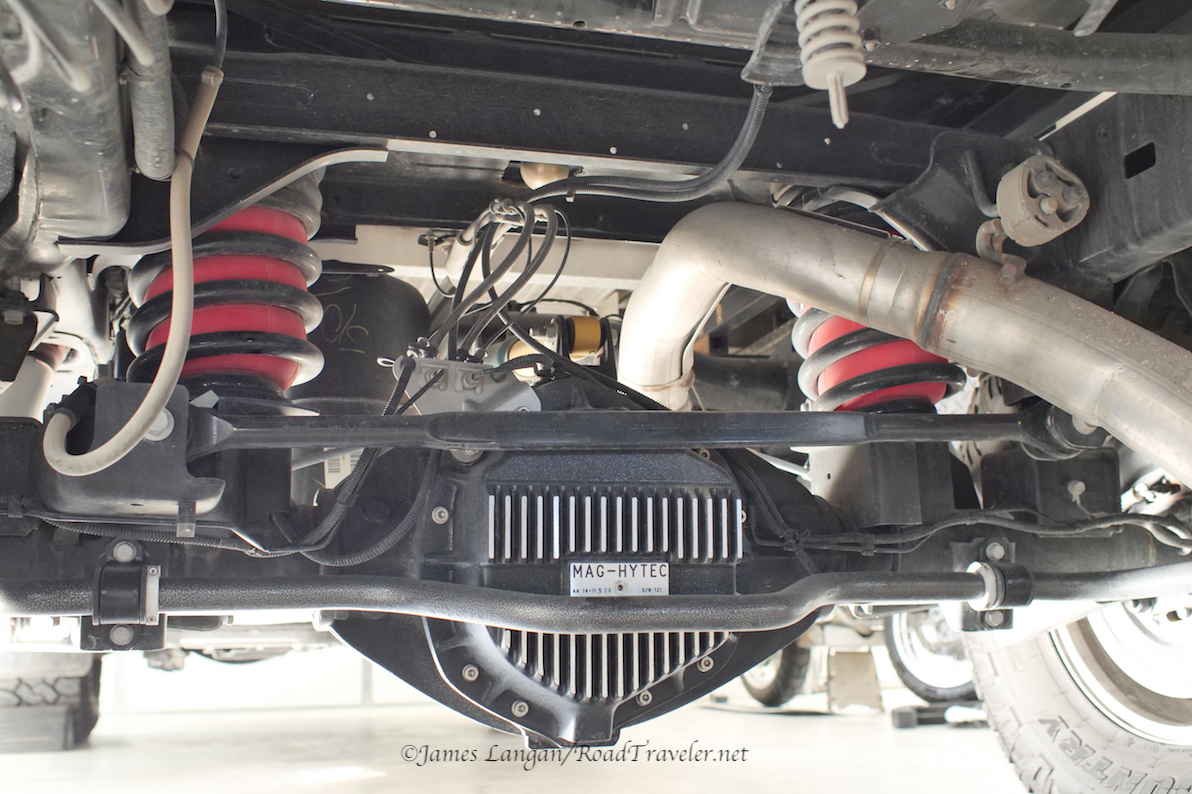

At the SEMA Show a few years ago TUFTRUCK introduced heavy-duty rear springs for the 2014 and newer Ram 2500 trucks. They had already been making replacement coils for the front axles of Ram trucks and other brands for several years.

TUFTRUCK is a brand of McAllister Industries out of British Columbia, Canada. This company has over 100 years of manufacturing experience, making leaf and coil springs for everything from light trucks up to huge mining equipment from quality American steel.

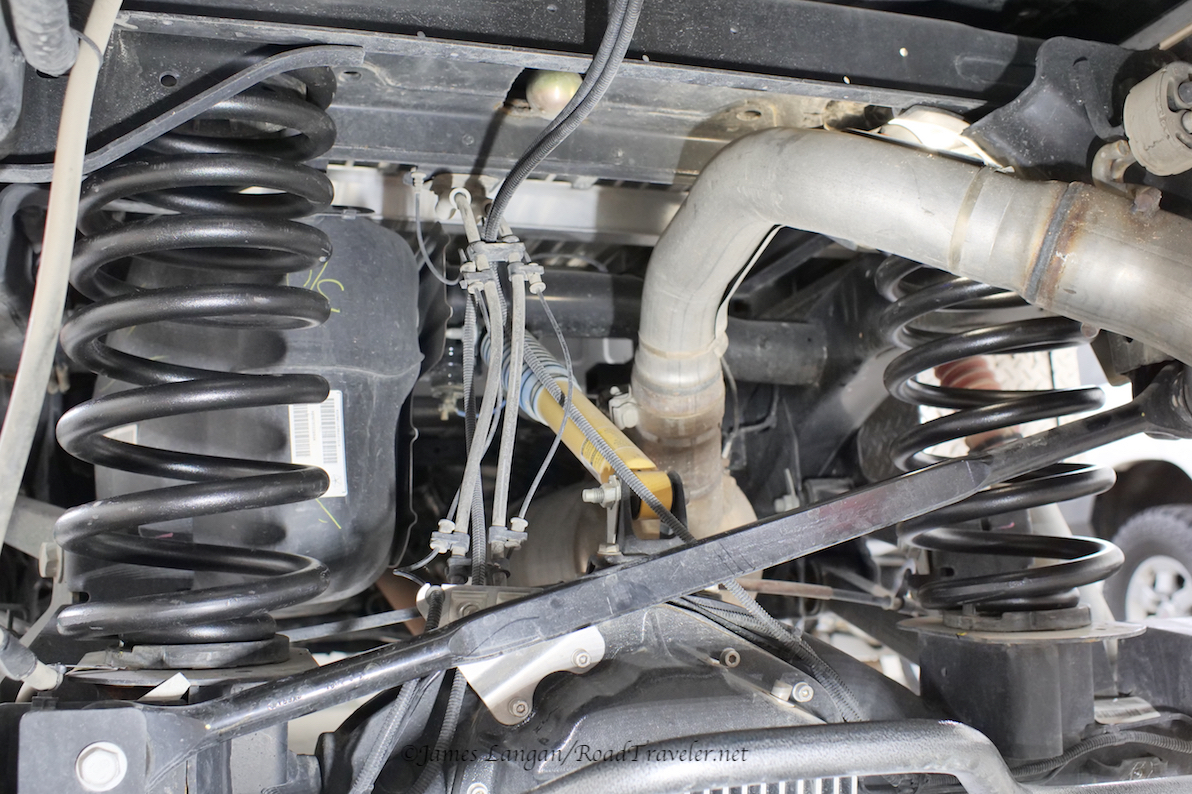

The TTC–1225 springs fit the 2014-and-newer, Ram 2500 trucks with coils atop the rear axle and cost about $425 a pair. They have a spring rate of 438 pounds-per-inch, and according to TUFTRUCK they add an additional 500 pounds of capacity. The chart below tells how much beefier the TUFTRUCK coils are compared to the stockers, and the differences are easy too see, feel, and measure.

| TTC-1225 vs OE Coil | TUFTRUCK TTC-1225 | OEM 2014 Rear Coil |

| Height | 18” | 17.75” |

| Diameter | 8” | 7.5” |

| Material Thickness | 0.93” | 0.86” |

| Weight | 35-lb | 24-lb |

Installation And Road Tests

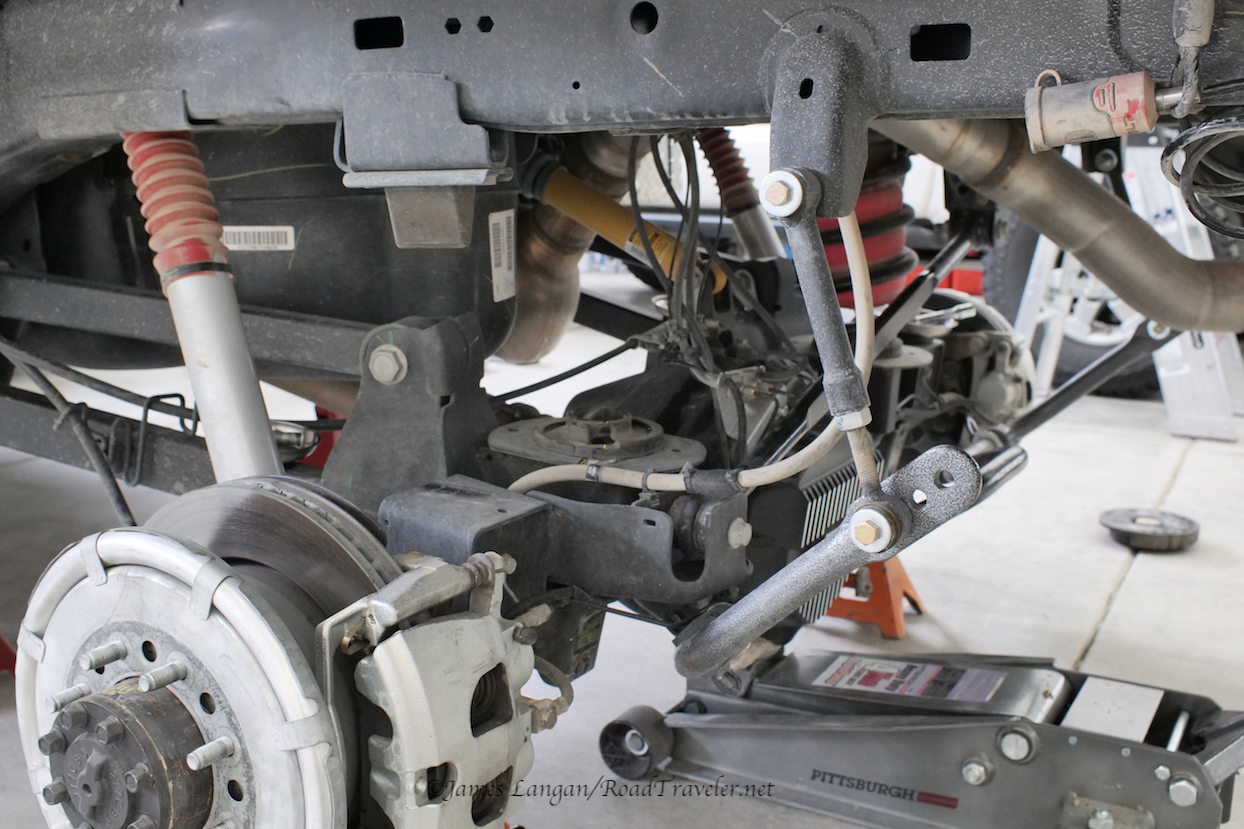

Swapping the rear coils on heavy-duty Rams is a simple job for the mechanically inclined and experienced; it is much easier than removing and replacing long, heavy, and awkward leaf packs. I did the project by myself, without a vehicle hoist and with zero cursing. If I had been removing-and-replacing leaf springs, particularly solo, there certainly would have been busted knuckles and profanity.

After chocking the tires on the front axle, lifting the rear of the truck, supporting the frame with jack stands, disconnecting the rear shocks and body-roll bar, and removing the rear wheels, the axle was drooped as far as practical to make the coils loose enough to remove. (Remember to insure you’re not pulling on brake or ABS lines.) Because the TUFTRUCK coils were just fractionally taller, and drooping the axle provided plenty of access, no spring compressor was needed. I spent much more time making measurements, videos, and photographs than doing mechanical work.

To make a direct, back-to-back comparison of the factory coils and the TUFTRUCK TTC-1225, the Air Lift auxiliary springs were deflated (to zero) before I drove a 15-mile test loop over a mix of city streets, rural highways, and interstate freeway. This type of repeatable initial testing, combined with notes made during the drive, helped document performance differences with an eye on reducing the effects of faded memories and subjectivity.

After installing the TTC–1225, there was a noticeable and substantial improvement in stability, control, and spring rate compared to the OEM coils. The stouter and fractionally taller TTC-1225 coils produced a 3/4” height increase measured at the bottom of the hitch receiver, with my Hallmark camper mounted (without water or gear).

Shortly after the installation I made a 1,000 mile roundtrip over the north-south length of Nevada, to buy a new Welsh Terrier puppy, our first travel-size dog. Then a 1,500-mile round trip to the Southwest in May. The TUFTRUCK rear springs are working well, and I’m glad I added them. Stay tuned, there are additional rear suspension upgrade editorials coming.

Tell ’em you saw it on RoadTraveler.net

Become a RoadTraveler patron. Thanks!

James Langan

Copyright James Langan/RoadTraveler. All Rights Reserved

Resource: