Mickey Thompson Baja Boss A/T LT255/85R17

The Baja Boss A/T was introduced to automotive journalists during the virtual 2020 SEMA Show with a press embargo date of April 5, 2021. After the embargo Mickey Thompson sent me a set for a long-term evaluation, which was published in the Turbo Diesel Register magazine. For my initial review I chose a popular 18-inch size aiming for the broadest appeal for those with newer trucks. In that piece I shared that Mickey Thompson introduced a new niche size, the LT255/85R17, that I also wanted to evaluate.

Overview

The Baja Boss A/T is a fairly high-void, four-rib tread design that Mickey Thompson calls a hybrid, AKA a commercial traction or an aggressive all-terrain. Absorbed by sister brand Mickey Thompson a few years ago, the legendary but now defunct Dick Cepek company arguably invented the first hybrid tread in 1978, when Mr. Dick Cepek introduced the first Fun Country. This was long before anyone used the word hybrid to describe tires, and before several other manufacturers started emulating these versatile and multifaceted designs.

When compared to a more conservative all-terrain or all-season, the deeper and higher-void tread offers better resistance to hydroplaning and superior grip on deeper snow and moderate mud. These attributes are often combined with rugged carcass construction, and if the right special sauce is used for the tread compound sometimes they also offer superior longevity.

Continually reducing road noise while improving other benefits of traction designs is a challenge for engineers. Historically there’s been no easy solution, because better traction in sloppy conditions requires bigger blocks and voids, which increases road noise. The Baja Boss A/T is quieter than it looks.

According To Mickey Thompson

Mickey Thompson says the Baja Boss A/T blends Extreme Sidebiters® for a bold look and serious grip with an all-new silica-reinforced compound providing long-wear, all-weather performance and cut/chip resistance.

Design highlights include:

- Large surface-area tread elements for a greater contact area

- Shoulder scallops for an additional biting edge

- Sound-deadening ribs for stability and a quiet ride

- Enhanced stone ejectors to reduce debris retention

- PowerPly XD™ with 50 percent heavier denier cord on the biased-angled third ply for protection, handling and stability

- Rim flange protector for added wheel protection

- 3 Peak Mountain Snowflake (3PMS) symbol certifies that all sizes 12.50 (315mm) and narrower are Severe Snow Service rated

- 50,000-mile treadwear warranty

- Increased-load LT-Metric sizing for heavy-duty applications

- Lower-load floatation sizing for half-ton, lighter trucks and SUVs

- A 35-inch tire approved for 17×6.5 dually wheels

That last bullet point is the specific size this review is about, the LT255/85R17 Baja Boss A/T (also know as the 35×10.00R17LT). The substantial siping helps achieve the severe winter rating and increases overall grip, and measures a whopping 17/32” of the total 18.5/32” depth. Calling the sidewall rubber Extreme Sidebiters® is not an exaggeration, as they are up to 14/32” thick!

LT255/85R17 For Duallys

Dual Rear Wheel (DRW) pickups have an import role in the heavy-duty market, above the more common and very capable single rear wheel (SRW) HD trucks, but a notch below what are really medium-dutys, the 4500 and 5500 chassis. But the rear duals greatly restrict aftermarket tire options due to the spacing needed between sidewalls.

Unless someone wants to have their outside tires protruding well beyond the fenders (some do, and they think it looks cool), the DRW crowd has few choices for taller rubber that will fit otherwise stock or lightly-modified trucks. Mickey Thompson invented the new LT255/85R17 size to fill this niche. It is 35-inch-tall (34.6”), and was purposely designed to fit narrow 6.5-inch dually wheels, though it works well on wheels up to eight inches wide for SRW pickups.

When inflated to 80 psi, the 121 load-index supports 3,195 pounds each in SRW applications, or 2,910 pounds for duals. The tread has one nylon, two steel, and three polyester plies, the sidewall construction has three polyester plies, and they are made in the U.S.A.

Single Rear Wheel Use

Narrower tires will almost always clear more easily with fewer and sometimes zero modifications than a wider tire of the same height. What is also routinely overlooked because many are focused on looks, and wider is perceived as tougher and better, is that a narrower footprint usually rolls down the road more consistently, catching fewer edges, rain grooves, or semi-truck ruts. There are some people that still prefer the appearance and performance of moderate width tires (few modern LT tires are actually narrow or small), and avoid negative-offset wheels or grossly wide rubber sticking well beyond the fenders, which sling rain, snow, mud and other debris.

So it was not surprising to hear Senior Project Manager, Light Truck Division at Mickey Thompson, Ben Anderson, say that the Baja Boss A/T in LT255/85R17 has become popular with the Jeep and Toyota crowd, and others wanting taller but not needlessly wide off-road meats for their four-wheel-drives. I’m also one of those folks.

Sidebar

17-inch Tires Limited to 3,195 Pounds

Why are most heavy-duty seventeens rated to support much less weight than a similar 18-inch, or even less than the same 17-inch size was in the past? Nearly all new 17-inch light-truck tires are limited to a maximum capacity of 3,195 pounds regardless of their size, psi, or theoretical capabilities.

It appears that several years ago the Tire and Rim Association (TRA) decided to lower the maximum load index for seventeens. Or maybe there was a government regulation necessitating the change? Whatever the reason, it is difficult to find high-capacity 17-inch rubber.

The official TRA load inflation charts indicate that something doesn’t compute. For example, the LT295/70R17E has 3,195 pounds of capacity when inflated to 65 psi. However, increasing the pressure to the maximum allowable 80 psi offers no increase in capacity. My basic understanding of math and science tells me that this is not how pressure and volume works inside a tire. Plus there are exceptions to the 3,195 limit.

3,970 Pound 17-Inch Anomaly

I think that if a specific tire design and/or size existed before the change, that manufacturers were grandfathered. Specific examples can be seen online, including from Toyo in their Open Country M/T line. Still using LT295/70R17E, the Toyo M/T has a load index of 128, and is rated to support 3,970 pounds at 80 psi, which makes much more sense. That is a whopping 775 pounds more than 3,195, and 1,550 pounds or 3/4-ton per axle!

For a given diameter, smaller wheels yield taller sidewalls, generally flex more, and may generate extra heat. Excessive heat is the archenemy of tires, so I theorize that this was one reason to push folks to bigger rims.

Yet there are big 16-inch sizes rated above the 17-inch, 3,195 maximum. The LT305/75R16 is rated for 3,640 pounds at only 65 psi. What gives? Are you a tire engineer reading this article? If so and you want to share some industry knowledge and history, I’d love to hear from you.

Possible Solutions

Many newer pickups come with 18-inch or larger wheels and there are many sizes that offer excellent carrying capacity. However, there are plenty of older trucks still running around on their original 17-inch rims, and they might need more capacity when hauling big loads. Proceed at your own risk, you are your own warranty station, nobody is responsible but you, etc. Depending on the specific tire, size, and manufacturer, and how one applies the science, it is possible that you may already have, or could source a 17-inch tire with more capacity than 3,195 pounds.

Mount And Balance

The Baja Boss A/T tread is asymmetric and there is a dedicated inside and outside sidewall, so they should be mounted correctly. It is possible to have a tire and wheel that is balanced according to the machine, but drives poorly. One reason can be attaching excessive weight to achieve the balance, and road force is another. As discussed in a previous article, excessive road force, or radial force variation, is a condition that can affect steering, traction, braking and load support. High road force will impart ride disturbances to the chassis and ultimately the driver.

Both the wheel weight required and the road force measurements were extremely low for this set of Mickey Thompsons. An acceptable maximum road force measurement for passenger car tires is 35 pounds, but all of these Baja Boss A/Ts were in the teens, which is phenomenal for a stout light-truck tire weighing 64 pounds. They were mounted on 28-pound OEM Fourth Generation 17-inch Power Wagon wheels, and the average weight needed to balance the resulting 93-pounds was only 3.9-ounces!

#1- 4.5 oz., road force 17-lb

#2- 3.75 oz., road force 11-lb

#3- 4.00 oz., road force 14-lb

#4- 3.25 oz, road force 16-lb

Data is nice, but like with many things these days we must ensure that the machines are accurate and confirm for ourselves that everything is truly working well.

Take It To The Limit, One More Time

My initial seat-of-the-pants freeway evaluation confirmed that Discount Tire’s balance machine was calibrated. These 255/85R17 Baja Boss A/T were fantastically smooth all the way up to 100 miles per hours and straight line tracking was excellent. I was running 58 psi in the fronts, and 40 psi in the rears, plenty for my 2500’s everyday unloaded wet weight.

The Toyo C/T is a similar heavy-duty commercial traction design and one of my all-time favorites, and a set was removed to mount the Mickey Thompsons. While the C/T are not loud for their capabilities, the Baja Boss A/T are noticeably quieter.

Not Loud

The lack of noise from the Baja Boss A/T for the amount of void and traction impressed me back in 2021. There are similar, older treads that I still like and have run extensively in multiple sizes on several four-wheel-drives, and the Cooper Discover S/T MAXX is a great example. The S/T MAXX is a little louder when new, but once they are worn the volume increases substantially, sometimes becoming nearly as loud as a mud-terrain. The Baja Boss A/T starts and remains quieter than others, and the engineers really deserve credit. Are they as quiet as a five-rib A/T or highway tread? Of course not. As with all tires, to help reduce noise and keep your rubber wearing evenly, frequent and consistent rotations are necessary.

Ride Quality

What constitutes a good or poor ride characteristic depends on one’s performance perspective. Some prefer a softer and more compliant on-road ride, while others want or need firmer and ostensibly stronger options. Even within the LT tire category there can be huge differences between tread designs and carcass construction, even when the load index and other ratings are identical. The Mickey Thompson Baja Boss A/T is sturdy, which I prefer when using my pickup for hauling, towing, and rugged off-pavement use. The PowerPly XD™ with its 50% heavier denier cord and biased-angle third sidewall ply can be felt, but that’s to be expected and is appropriate for the intended applications.

I do prefer a somewhat softer ride during normal daily driving, but this is easily accomplished with the following two practices. I don’t combine super tall wheels with short and silly thin sidewalls (which also reduces carrying capacity), and I run close to the minimum pressure required for the weight on each axle. This means I know what my vehicle weighs, find the appropriate psi using an inflation chart, and am diligent about adding air when the load is substantially increased.

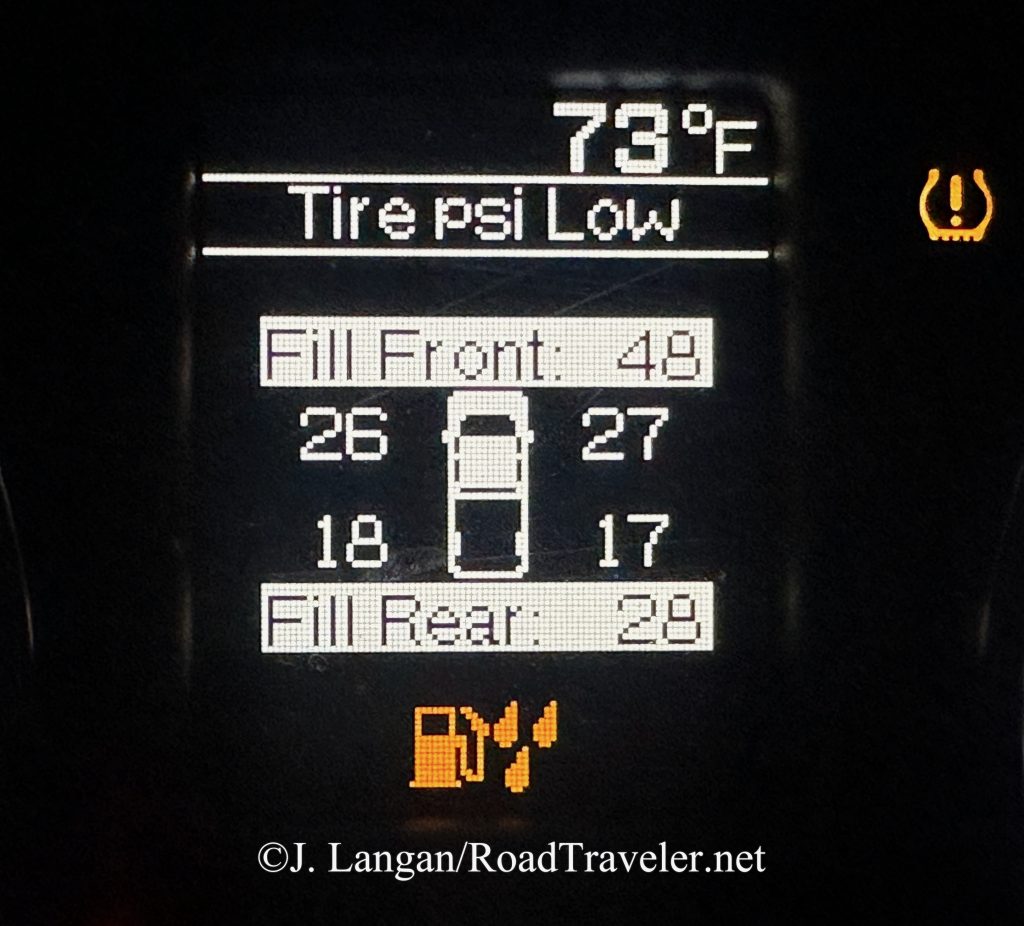

How Low Can You Go?

When unloaded I routinely run my rears between 35 and 40 psi for comfort, traction, and overall performance. The fairly soft riding 2014-and-newer Ram 2500s are not nearly as rough as the older and stiffer suspensions, but it’s still suboptimal to have overinflated tires. The ride quality difference between 80 and 40 psi with no load on the rear axle is dramatic. Over-inflation hurts grip and uneven wear is also possible.

Depending on the exact size, load index 121 tires will have a capacity of about 1,950 pounds each, or 3,900 pounds per axle at 35 psi, more than many think. One can always increase pressure to tune for their speed, ride, and overall preferences. Tires get hotter in warm weather and at higher speeds, and overheated tires can and do separate. Increasing psi for certain conditions might be desirable, but that doesn’t mean jumping from 35 psi to 80 when there is only 3,500 pounds on the axle.

In the front I typically run between 50 and 60 psi depending on the ratings and weight. The Cummins Turbo Diesel is heavy, but front axle loads are less variable so pressure adjustments are rarely needed.

Light Load TPMS Light

The federally mandated Tire Pressure Monitoring System (TPMS) is an outgrowth of the Ford Explorer/Firestone debacle in the 1990s. It’s also symbolic of a larger problem, which is the unwillingness of the average driver to take responsibility for their machinery, including failing to check something as fundamentally important as tire pressure. Even with TPMS on my pickups, I regularly check and adjust pressures with a handheld gauge.

Having psi information available on the dash is great, but it’s unfortunate that Ram eliminated the light-load option around 2012, and require all 2500 owners to run pressures for maximum loads or accept a warning light on the dash. The 3500 Rams have a different system, the Tire Pressure Information System (TPIS), because their GVWR is over 10,000 pounds. TPIS provides information but does not force a warning light for running less than a predetermined and maximum pressure.

I permanently eliminated the TPMS irritant with a professional Autel MaxiSys MS906 tablet scan tool. One could argue that this was a $1,000 sledgehammer solution to dispatch an ant. True, but I purchased the Autel one year before the AlphaOBD diagnostic software was available, which reportedly works well for adjusting the pressure thresholds.

A professional automotive tablet is a super powerful diagnostic tool, and I have only used a small fraction of its capabilities. But the scanner has come in handy a few times by allowing me to discover the source of unusual problems or clear codes that were too much for my Edge CTS2.

Regardless of the tool being used, I absolutely love being able to adjust the minimum psi thresholds for both the front and rear axles to my liking, depending on the load index of the tires and my needs. My 2017 regular cab has a heavy Hallmark flatbed camper mounted full-time and the rear axle threshold’s are set higher, usually around 70 or 80 psi.

Need Traction?

Traction, handling, and overall performance from the Baja Boss A/T has been impressive in all conditions and on every surface, which has included considerable dirt, gravel, rock, rain, and snow. For those wanting hybrid or commercial traction rubber I don’t envision many people wanting more grip over varied terrain than these Mickey Thompsons provide. My first set of Baja Boss A/T saw less snow than I would have preferred, not taking advantage of the three peak mountain snowflake (3PMS) rating because our local Sierra Nevada winter storms and my travels rarely overlapped in 2021. The story is dramatically different with the second set.

Got Snow and Rain? Lots Of It?

The day after mounting these LT255/85R17 on my 2014 crew cab, I made a 500 mile weekend round trip that included two crossings of the Sierra Nevada’s infamous Donner Pass. There were several inches of wet snow for dozens of miles that required four-wheel-drive. Followed by 100 miles of epic rainfall. The kind of rain that even with the windshield wipers bouncing at full speed I could barely see the roadway, similar to dangerous fog conditions, and using four-wheel-drive was beneficial because of water on the road. Throughout the remainder of winter and spring 2024, the Baja Boss A/T performed perfectly during every winter storm.

Similar to mud, the types of snow and the related driving conditions can vary greatly by region or microclimate, and opinions regarding what is good performance in certain conditions are highly subjective. For my uses I have found that the Mickey Thompson Baja Boss A/T are an excellent winter and wet weather performer under my Ram 2500.

Sidebiters®

Sidewall tread has become popular in recent years, even on tires that are really not intended to be used in harsh off-pavement conditions because it looks cool. However, the Baja Boss A/T Extreme Sidebiters® are legit, and are super thick and beefy. I certainly like how they look, but also put them to work for their intended purpose. If you never leave the pavement, the Sidebiters® aren’t going to complain if you drag them along curbs.

Estimated Longevity Baselines

Wear and longevity for a given tire can be highly variable depending on the vehicle, duty-cycle, and driver. One could argue that all three of these metrics (and others) are important, however, the person behind the wheel has a disproportionate effect, and will invariably influence results dramatically compared to the others.

If we were to take two identical pickups (model, gearing, transmission, tires, etc.), load them the same, and run them over a route with different drivers, it would not be surprising to see measurably different fuel economy. Covering longer distances and varied terrain would make the differences more obvious. More or less mpg is a direct result of how one operates the accelerator and brakes.

Tires and brakes are consumed more slowly than fuel, but over time the driver who gets fewer mpg and exercises less finesse and vehicle sympathy will likely also get fewer miles out of their rubber and brakes. The differences can be dramatic.

Same Guy Driving The Same Truck

No one’s truck, conditions, or driving style are identical, however, if the driver is not one of the variables the data can be more comparable. The treadwear information I’ve gathered from several four-wheel-drives over decades, particularly during the last 10 years driving the same 2014 Ram 2500 crew cab with a G56 6-speed manual transmission, provides relatively consistent and relevant information.

Wear Data

These LT255/85R17 Baja Boss A/T were mounted February 2024, have been rotated twice, and have logged 6,300 miles. Approximately 10% of those were off-pavement, including dozens at low trail pressures to improve ride, traction, and prevent damage. There is zero visible cutting, chipping or lug tearing of the tread, which is impressive considering the amount of off-highway use my truck sees. (Again, driving habits matter, and I keep tire slip and spinning to a minimum, particularly in the dirt.)

While I am smooth and conservative off-pavement, on the blacktop I routinely use all of the torque, horsepower, and rpm that my G56 version of the Cummins 6.7L has to offer with assertive application of the skinny pedal. Just like hard braking and turning fast can disproportionately wear the fronts, the massive twist of modern diesel engines can be hard on the rear drivers. Yet, that is not what I’ve experienced, there has been no penalty for my lead foot.

All Baja Boss A/T come with 18.5/32” of tread, and this set currently has about 15.5/32”, so they have given 2,100 miles per 1/32”. Those 2,100 miles compare well with other quality aftermarket traction designs, on the same truck, driven by me.

For comparison, my previous set of Baja Boss A/T in 295/70R18 were run for 15,000 miles and delivered 2,300 miles for each thirty-second before they started living on a friend’s 1991 W250 Turbo Diesel. If 2,100 miles per 1/32” remains constant, these 255/85R17 Baja Boss will last 36,800 miles before reaching the minimum legal depth of 2/32”.

Still Love Them

After running two sets of Baja Boss A/T over the past few years I’m still enamored with this design from Mickey Thompson, and it might become my favorite hybrid all-terrain. They wear well, provide excellent traction and performance in all conditions, and are extremely rugged while still being quieter than competitors. Currently they are available in 74 sizes, for wheels from 15 to 24 inches. If you are in the market for a new set of tires you owe it to yourself to consider the Baja Boss A/T from Mickey Thompson.

Tell ‘em you saw it on RoadTraveler.net!

Copyright J. Langan/RoadTraveler. All Rights Reserved

Resource:

Mickey Thompson Tires: mickeythompsontires.com